Hi fellow game devs,

I'm working on a car simulator using Unity3D and currently stuck on implementing the clutch.

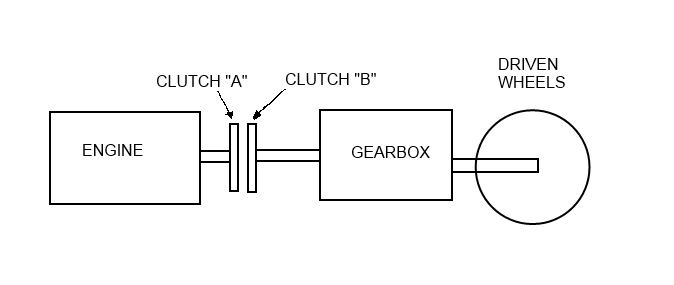

Currently, my drivetrain model involves torque from engine and reaction torque from the drivetrain and is using Unity3D wheelCollider. My ultimate goal is to calculate engineRPM at each time step, from there lookup engineTorque from torque curve and send to the wheels through drivetrain. Known variables are wheelRPM (reported from wheelCollider, read only), wheelInertia (calculated from wheelMass and radius, reported from wheelCollider), and engineTorque from a torque curve. Right now for simplicity, I'm ignoring drivetrain inertia and the differential is open.

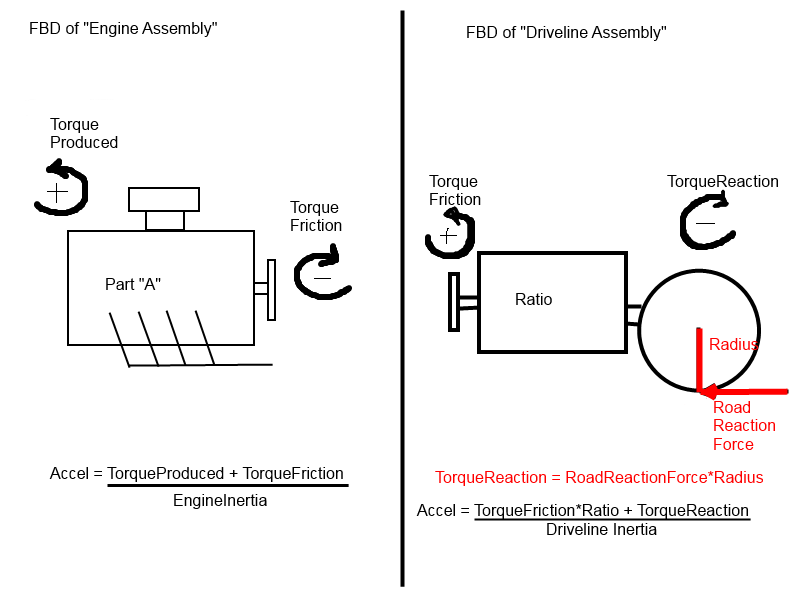

This is my currently non-working procedure, I'm using the formula AngularAcceleration = Torque/Inertia, so each timestep engineVelocity += AngularAcceleration.

wheelAngularMomentum is calculated using Momentum = Inertia * AngularVelocity. Take the sum angular momentum of all the driven wheels, convert that angular sum to torque by divide torque to detalTime, because deltaMomentum= Torque * deltaTime, so Torque = deltaMomentum / deltaTime (I don't know if I'm right or not here). This torque will be wheelReactionTorque.

For engineCombustionTorque, I use a curve to look up torque at certain RPM. Then engineTotalTorque will be engineCombustionTorque - frictionTorque. This sum of torque is the torque at the engine acting on the flywheel.

engineTotalTorque then drives the flywheel with its inertia engineInertia. This engineTotalTorque is resisted by the above wheelReactionTorque. So the netTorque is engineTotalTorque - wheelReactionTorque. This netTorque still drive only the flywheel which is engineInertia, but is resisted by the reaction torque from the wheels. So now the engineRPM is calculated using the formula AngularAcceleration = Torque/Inertia this way: engineRPM += netTorque / engineInertia * deltaTime.

The biggest problem now is I don't know which force/torque will be transfered to the wheel and drives the wheels. Can you please help me out here?

Second, I don't know where and how to put the clutch in-between, I'm thinking of have a clutchInput float in wheelReactionTorque, so when it's 0 ie clutch disengaged, no resistance torque, engine freely spin the flywheel. clutchInput > 0, percentage of resistance is there, engine now drives itself and the resistance. What do you think about this?

Third, should the wheelResistanceTorque be modified with gearRatio before going back to the engine, say wheelResistanceTorque / gearRatio, or wheelResistanceTorque * gearRatio? If yes, should it be divide or multiply? I know that engineTorque going to wheel will have to be multiply with gearRatio, but what about the torque from wheel going back looking from the engine side?

I'm planning to stick with built-in wheelCollider despite its drawbacks to save time. I would like to make some sort of "sim-cade" handling similar to GRID or TDU, where the physic and handling is arcade-y, but still involves real physic factors such as managing clutch, tuning suspension, etc, as oppose to fully arcade games like need for speed or burnout.

Thank you guys very much in advance.